Revolutionizing Industries with 3D Printing Wings

In the world of advanced manufacturing, 3D printing wings exemplify the remarkable potential of additive technology. This innovative approach is redefining traditional manufacturing paradigms, particularly in industries such as aerospace, automotive, and product design. The ability to create complex geometries and lightweight structures has opened doors to new possibilities, fostering creativity and sustainability. Meanwhile, businesses like 3DPrintWig.com are at the forefront of this transformation, pushing the boundaries of what is achievable with 3D printing technology.

The Fundamentals of 3D Printing in Manufacturing

3D printing, also known as additive manufacturing, involves creating three-dimensional objects from a digital file by adding material layer by layer. Unlike traditional subtractive manufacturing techniques, which carve away material to create an object, 3D printing allows for intricate designs that would be impossible or very costly to produce conventionally. This method utilizes a variety of materials, including plastics, metals, and composites, enabling a diverse array of applications.

Understanding the Importance of 3D Printing Wings

The concept of 3D printing wings serves as a perfect illustration of the advantages of additive manufacturing. Wings for aircraft, drones, and other vehicles can be produced with remarkable efficiency and precision. The advantages include:

- Lightweight Structures: 3D printed wings can be designed to use less material while maintaining strength, resulting in lighter aircraft that improve fuel efficiency.

- Complex Geometry: Additive manufacturing enables the creation of intricate wing shapes that optimize aerodynamics—from airfoils to complex lattice structures.

- Rapid Prototyping: Engineers can quickly iterate designs, testing and refining to achieve the desired performance characteristics without the lengthy lead times associated with traditional manufacturing.

- Customization: Tailoring wing designs for specific applications or client needs becomes much simpler, allowing for bespoke solutions.

- Sustainability: The reduced material waste associated with 3D printing aligns with modern sustainability goals, making it a greener option compared to traditional manufacturing processes.

Applications of 3D Printing Wings in Aerospace

The aerospace sector has been one of the leading adopters of 3D printing wings. Companies are leveraging this technology for various applications:

1. Aircraft Wing Components

Modern aircraft manufacturers utilize 3D printing to produce wing components that are both lightweight and robust. For example, parts that require intricate cooling channels or complex internal structures can be manufactured more efficiently through 3D printing than conventional machining methods.

2. Drone Wings

With the rise of drone technology, 3D printed wings have become increasingly popular. Drones require lightweight structures for extended flight times, and the design flexibility offered by 3D printing allows engineers to optimize wing designs to enhance performance and agility.

3. Prototyping and Testing

Before committing to full-scale manufacturing, companies can create prototypes of wing designs using 3D printing. This allows for extensive testing and refinement, reducing development costs and time to market.

4. Customizable Solutions for Specialized Applications

Whether for emergency services, agricultural drones, or unique aircraft configurations, 3D printing facilitates the creation of custom wing designs tailored to specific missions, enhancing operational effectiveness.

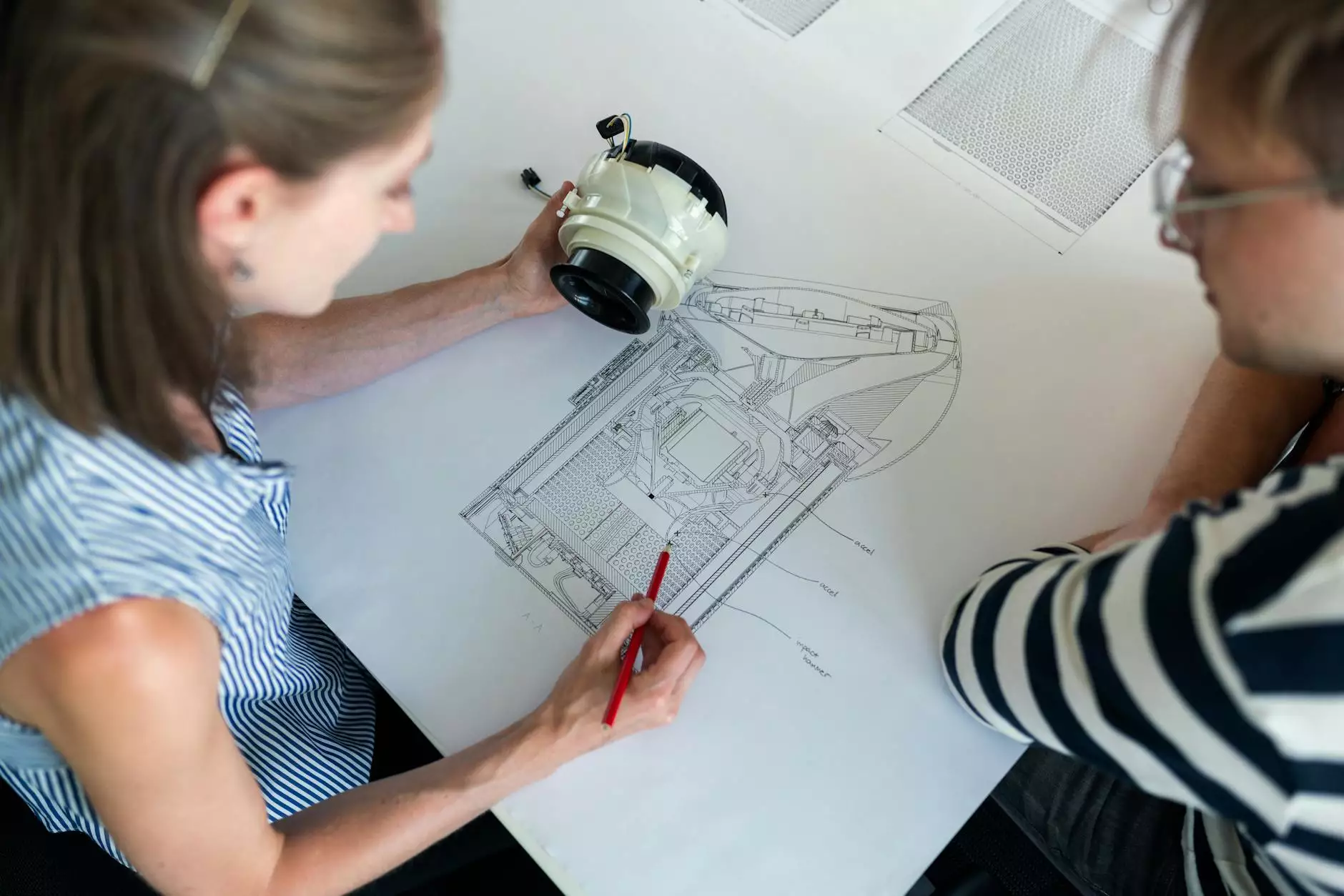

The Process of Creating 3D Printed Wings

The process of 3D printing wings involves several key steps:

1. Design Creation

The first stage involves creating a 3D model. Engineers and designers use Computer-Aided Design (CAD) software to develop detailed models that account for aerodynamics, material properties, and structural integrity.

2. Material Selection

Selecting the right material is crucial. The choice often depends on the specific application of the wing, with materials ranging from lightweight thermoplastics to advanced composites and metals.

3. Slicing the Model

Once a model is ready, it is sliced into thin horizontal layers using slicing software. This translates the 3D model into instructions that the 3D printer can understand.

4. Printing

The slicing software outputs G-code, which directs the 3D printer to deposit material layer by layer, building the object from the bottom up. Depending on the printer and the chosen material, this process can take anywhere from a few hours to several days.

5. Post-Processing

After printing, the wing may require post-processing steps such as sanding, polishing, or painting to enhance surface finish and achieve the desired performance characteristics.

Advantages of Using 3D Printed Wings

Adopting 3D printing wings offers numerous benefits for industries:

- Cost-Effective Manufacturing: Reducing production costs through less material waste and decreased labor time.

- Accelerated Innovation: Rapid prototyping capabilities lead to faster design cycles and innovation.

- Supply Chain Simplification: 3D printing can enable on-demand production, reducing the need for extensive inventory and warehousing.

- Enhanced Performance: Optimizing designs can enhance durability and performance, leading to longer lifespans for aircraft and drones.

Case Studies in 3D Printing Wings

Real-world applications of 3D printing wings illustrate the technology's disruptive potential:

1. Boeing and Airbus

Major players like Boeing and Airbus have invested heavily in 3D printing technologies. Boeing has developed 3D printed wing components, improving efficiency while reducing weight. Airbus, on the other hand, has showcased its commitment to additive manufacturing by designing and producing components for its A350 aircraft.

2. Drones and UAVs

Small-scale manufacturers of drones have successfully adopted 3D printing techniques for wing production. This has enabled custom designs tailored for specific applications such as mapping, surveillance, and package delivery, demonstrating the broad applicability of 3D printed wings.

The Future of 3D Printing Wings in Business

The future of 3D printing wings looks promising as technology continues to evolve. Trends indicate rapid advancements in materials science, improving the properties of printable materials, thus expanding their range of applications. As industries increasingly prioritize sustainability and efficiency, the integration of 3D printing methodologies into manufacturing processes seems destined to grow.

Conclusion

As we have explored throughout this article, 3D printing wings exemplifies the convergence of technology and innovation, pushing industries towards more sustainable and efficient practices. Companies like 3DPrintWig.com are leading the charge, offering cutting-edge solutions that redefine traditional manufacturing limitations. With its transformative potential, 3D printing will undoubtedly shape the future of various sectors, enhancing creativity, efficiency, and sustainability.

For businesses keen on staying ahead, embracing the advancements in 3D printing is not just an option; it's a necessity. As more industries discover the benefits of 3D printing wings, we can anticipate a future filled with exciting developments and opportunities for innovation.