CNC Precision Machining Suppliers: Elevating Your Business with Expert Metal Fabrication

The world of manufacturing has witnessed significant advancements, particularly in the realm of CNC (Computer Numerical Control) precision machining. This cutting-edge technology enables manufacturers to produce parts and components with exceptional accuracy and repeatability. For businesses looking to enhance their production capabilities, partnering with reliable CNC precision machining suppliers is crucial. In this comprehensive guide, we delve into the intricacies of CNC precision machining and the pivotal role these suppliers play in the manufacturing sector.

The Importance of CNC Precision Machining

CNC precision machining is a manufacturing process that utilizes computer software to control machine tools. It offers various benefits that significantly contribute to business success:

- High Precision: CNC machines produce parts with tolerances as tight as ±0.001 inches, which is essential for industries such as aerospace, automotive, and medical devices.

- Scalability: With CNC machining, businesses can rapidly scale production to meet demand without compromising quality.

- Complex Geometries: CNC precision machining can fabricate intricate shapes and complex designs that would be nearly impossible to achieve with traditional machining methods.

- Reduced Labor Costs: Automation in CNC machining minimizes the need for manual labor, leading to significant cost savings.

Choosing the Right CNC Precision Machining Suppliers

Identifying the right CNC precision machining suppliers is more than just comparing prices; it involves understanding their capabilities and how they align with your business needs. Here are key factors to consider:

1. Expertise and Experience

Look for suppliers with extensive experience in the CNC machining industry. Seasoned suppliers often have a proven track record and a portfolio showcasing their capabilities. They should be familiar with a variety of materials, including metals, plastics, and composites, ensuring they can accommodate your specifications.

2. Quality Assurance

Partnering with suppliers who prioritize quality is paramount. ISO certification is an essential indication of quality management systems. Furthermore, inquire about their quality control measures, such as:

- Regular inspections and testing of parts

- CMM (Coordinate Measuring Machine) inspections

- Final assembly checks

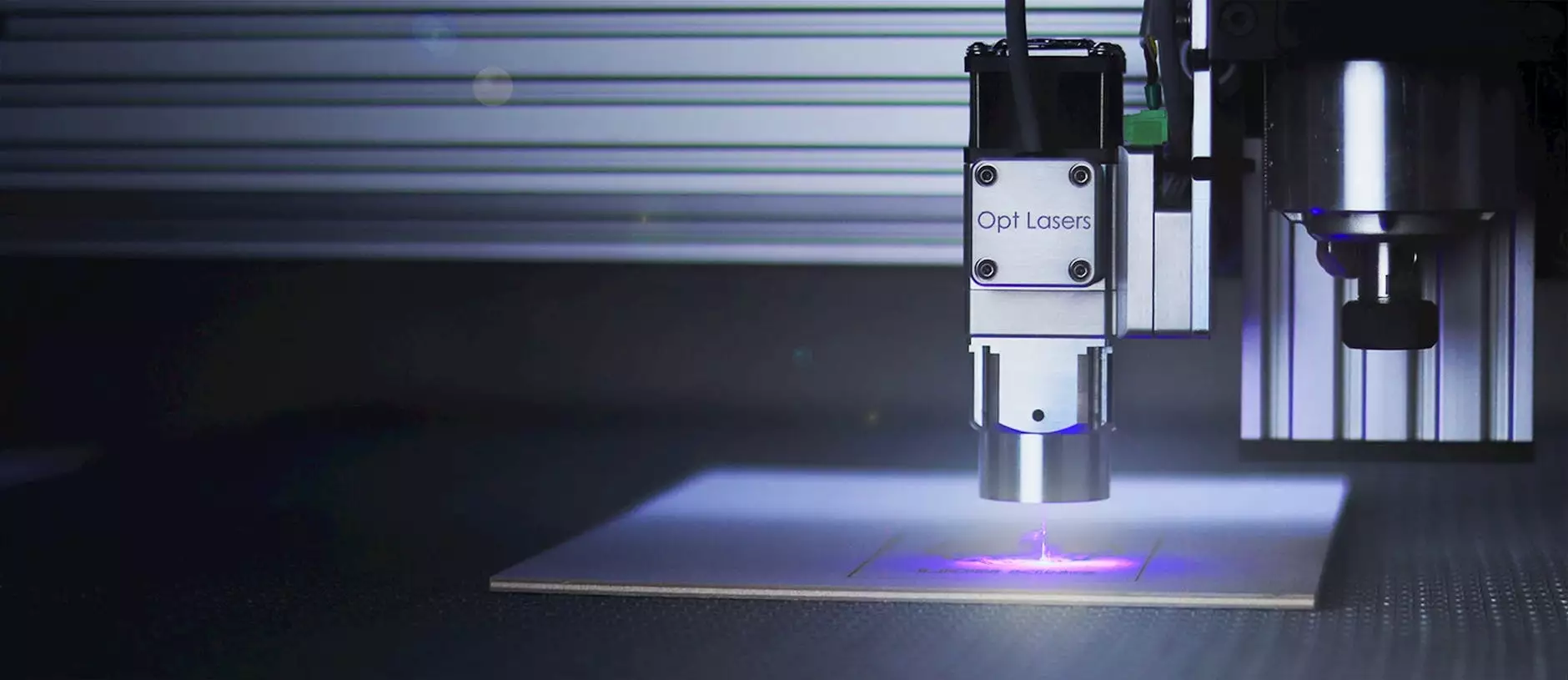

3. Technology and Equipment

The technology and machinery used by CNC precision machining suppliers play a crucial role in the quality of the output. Suppliers should invest in state-of-the-art machines, including multi-axis CNC mills and lathes, which offer greater versatility and can handle a wider range of projects.

4. Lead Times and Flexibility

Understanding the lead times required by your supplier is critical to maintaining efficiency in your production schedule. Choose suppliers who can meet your deadlines without compromising quality. Additionally, suppliers who exhibit flexibility in adjusting to unexpected changes will be invaluable partners.

5. Customer Support and Communication

Effective communication is a key aspect of successful collaboration. Suppliers should provide reliable customer support, including:

- Timely responses to inquiries

- Clear updates on project status

- Post-production support

Innovative CNC Precision Machining Technologies

Staying abreast of the latest advancements in CNC machining technology can provide a competitive edge. Some notable trends are:

1. Automation and Robotics

Integrating robotics into CNC machining operations enhances productivity and safety. Automated systems can perform repetitive tasks at high speeds, freeing up human operators to focus on more complex activities.

2. Additive Manufacturing Integration

Combining CNC machining with additive manufacturing techniques allows for greater creativity in part design. This hybrid approach enables the production of lightweight, complex geometries that reduce material waste.

3. Advanced Software Solutions

Modern CNC machines are outfitted with advanced software that enhances the programming and operational capabilities. Software development for CAM (Computer-Aided Manufacturing) often incorporates features such as simulation and real-time analytics, leading to improved efficiency.

Industries Benefiting from CNC Precision Machining

CNC precision machining serves a wide array of industries, including:

Aerospace

The aerospace industry demands uncompromising precision and reliability. Components such as turbine blades and engine parts require high tolerances that only CNC machining can fulfill. Working with a knowledgeable machining supplier ensures adherence to stringent industry standards.

Automotive

As the automotive industry modernizes, the demand for precision-engineered parts has surged. CNC machining suppliers facilitate the production of complex components such as transmission gears, which improve vehicle performance and safety.

Medical Devices

In the medical sector, where precision is essential, CNC machining enables manufacturers to create components for surgical instruments and implants with extreme accuracy and surface finish, minimizing the risk of complications.

Electronics

The electronics industry relies on CNC precision machining to produce parts that fit within tight tolerances while ensuring functionality. Micro-machining techniques can fabricate components for smartphones, computers, and other electronic devices, showcasing the versatility of CNC suppliers.

Benefits of Partnering with DeepMould.net

When considering CNC precision machining suppliers, DeepMould.net stands out due to its commitment to excellence in metal fabrication and machining. Here are the advantages of partnering with us:

1. Comprehensive Service Offering

DeepMould.net provides a full suite of services encompassing prototyping, production, and post-processing. Our team is equipped to handle projects of varying complexities, ensuring you have a single source for all your machining needs.

2. Customer-Centric Approach

At DeepMould.net, we prioritize our clients' needs. Our experts work closely with you throughout the production process, ensuring open lines of communication and swift resolution of any challenges that arise.

3. Commitment to Sustainability

As industries shift toward sustainability, DeepMould.net is committed to environmentally responsible practices. Our machining processes aim to minimize waste, and we continually seek methods to improve energy efficiency.

4. Industry Expertise

With years of experience in various sectors, we understand the nuances and demands of each industry we serve. We leverage our knowledge to deliver tailored solutions that meet your specific requirements.

Conclusion

In conclusion, partnering with CNC precision machining suppliers like DeepMould.net elevates your business in the competitive manufacturing landscape. By leveraging advanced technology, expert knowledge, and a commitment to quality, these suppliers play an indispensable role in helping businesses meet their production goals. Whether you operate in aerospace, automotive, medical devices, or electronics, the right CNC machining partner will provide you with the precision, reliability, and efficiency you need to thrive.

To explore how DeepMould.net can transform your production capabilities, visit our website today and get in touch with our experienced team. Your success is our mission!